Uma kukhulunywa ngokukhulisa ukusebenza kahle kanye nobude bezinhlelo zakho zemishini, ukukhetha ama-sprocket eketanga kubaluleke kakhulu. Ake singene ezicini ezibalulekile zezinto zokwakha, ubukhulu, izakhiwo, kanye nokugcinwa okuzophakamisa imisebenzi yakho iye ezingeni elisha.

Ukukhethwa Kwezinto Ezibalulekile: Uma kukhulunywa ngokuthuthukisa izinhlelo zakho zemishini, ukukhetha izinto ze-chain sprocket kubalulekile. Ufuna ukuqinisekisa ukuthi amazinyo e-sprocket yakho anamandla anele okukhathala okuthintana nokumelana nokuguguleka. Yingakho insimbi yekhabhoni esezingeni eliphezulu, njengensimbi engu-45, ivame ukuba yisinqumo esithandwayo. Kulezo zicelo ezibalulekile, cabanga ngokuthuthukela kuzinsimbi ze-alloy ezifana ne-40Cr noma i-35SiMn ukuze kuthuthukiswe ukusebenza.

Amazinyo amaningi e-sprocket aphathwa ngokushisa ukuze afinyelele ubulukhuni bomphezulu obungu-40 kuya ku-60 HRC, okuqinisekisa ukuthi angakwazi ukumelana nobunzima bokusebenza. Kubalulekile ukuqaphela ukuthi ama-sprocket amancane athintana kaningi kunezinja zawo ezinkulu futhi abhekana nemithelela emikhulu. Ngakho-ke, izinto ezisetshenziselwa ama-sprocket amancane kufanele zibe ngcono kunezo ezisetshenziselwa amakhulu.

Kuma-sprocket adinga ukubekezelela imithwalo yokushaqeka, insimbi enekhabhoni ephansi iyindlela enhle kakhulu. Ngakolunye uhlangothi, insimbi ehlanganisiwe ilungele ama-sprocket aguga kodwa angabhekani nokudlidliza okukhulu. Uma uhlelo lwakho lokusebenza ludinga amandla aphezulu kanye nokumelana nokuguguleka, insimbi ye-alloy iyindlela engcono kakhulu.

Ukutshala imali ezintweni ezifanele zama-sprocket akho akugcini nje ngokuthuthukisa isikhathi sawo sokuphila kodwa futhi kuthuthukisa ukusebenza kahle kwezinhlelo zakho zemishini. Ungayeki ikhwalithi—khetha ngokuhlakanipha futhi ubuke ukusebenza kwakho kukhuphuka!

Ubukhulu Obubalulekile kanye Nezinketho Zesakhiwo

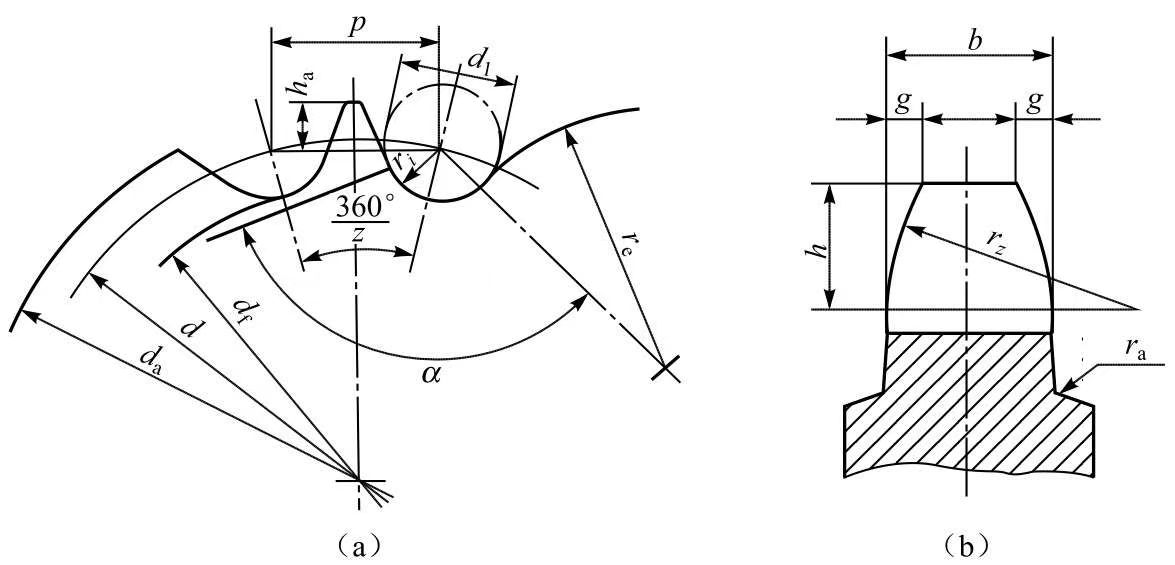

Ukuqonda ubukhulu obuyinhloko bama-sprocket akho kubalulekile ukuze kusebenze kahle. Ubukhulu obuyinhloko buhlanganisa inani lamazinyo, ububanzi bendilinga yephimbo, ububanzi bangaphandle, ububanzi bempande, ukuphakama kwamazinyo ngaphezu kwephimbo lephimbo, kanye nobubanzi bamazinyo. Indilinga yephimbo iyindilinga lapho isikhungo sezikhonkwane zeketanga silele khona, sihlukaniswe ngokulinganayo yiphimbo leketanga.Njengoba kuboniswe ngezansi:

Ama-sprocket eza ngezindlela ezahlukene zesakhiwo, kufaka phakathi izinhlobo eziqinile, ezinezimbobo, ezihlanganisiwe, nezihlanganisiwe. Kuye ngobukhulu, ungakhetha isakhiwo esifanele: ama-sprocket amancane anobubanzi angaba aqinile, ama-sprocket anobubanzi obuphakathi avame ukusebenzisa umklamo onezimbobo, kanti ama-sprocket amakhulu anobubanzi avame ukuhlanganisa izinto ezahlukene zendandatho yamazinyo kanye nengaphakathi, ezixhunywe ngokushisela noma ngebholti. Ukuze uthole izibonelo ezithile, hlola i-Goodwill'si-sprocketamakhathalogi.

Ukuklama Amazinyo: Inhliziyo Yokusebenza Kahle

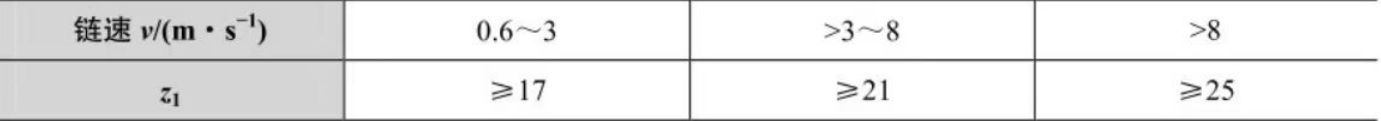

Inani lamazinyo ku-sprocket lithinta kakhulu ukushelela kokudluliselwa kanye nokuphila isikhathi sonke. Kubalulekile ukukhetha inani elifanele lamazinyo—hhayi amaningi kakhulu futhi hhayi ambalwa kakhulu. Inani elikhulu lamazinyo linganciphisa isikhathi sokuphila kweketanga, kuyilapho ambalwa kakhulu angaholela ekungalinganini kanye nokwanda kwemithwalo enamandla. Ukuze kuncishiswe lezi zinkinga, kungcono ukunciphisa inani elincane lamazinyo ku-sprocket ezincane, ngokuvamile ezibekwa ku-Zmin ≥ 9. Inani lamazinyo ku-sprocket ezincane (Z1) lingakhethwa ngokusekelwe kwisivinini seketanga, bese inani lamazinyo ku-sprocket enkulu (Z2) linganqunywa kusetshenziswa isilinganiso sokudluliselwa (Z2 = iZ). Ukuze kusetshenziswe ngokulinganayo, amazinyo e-sprocket ngokuvamile kufanele abe inombolo engavamile.

Isakhiwo Esifanele Sokushayela Kwe-Chain

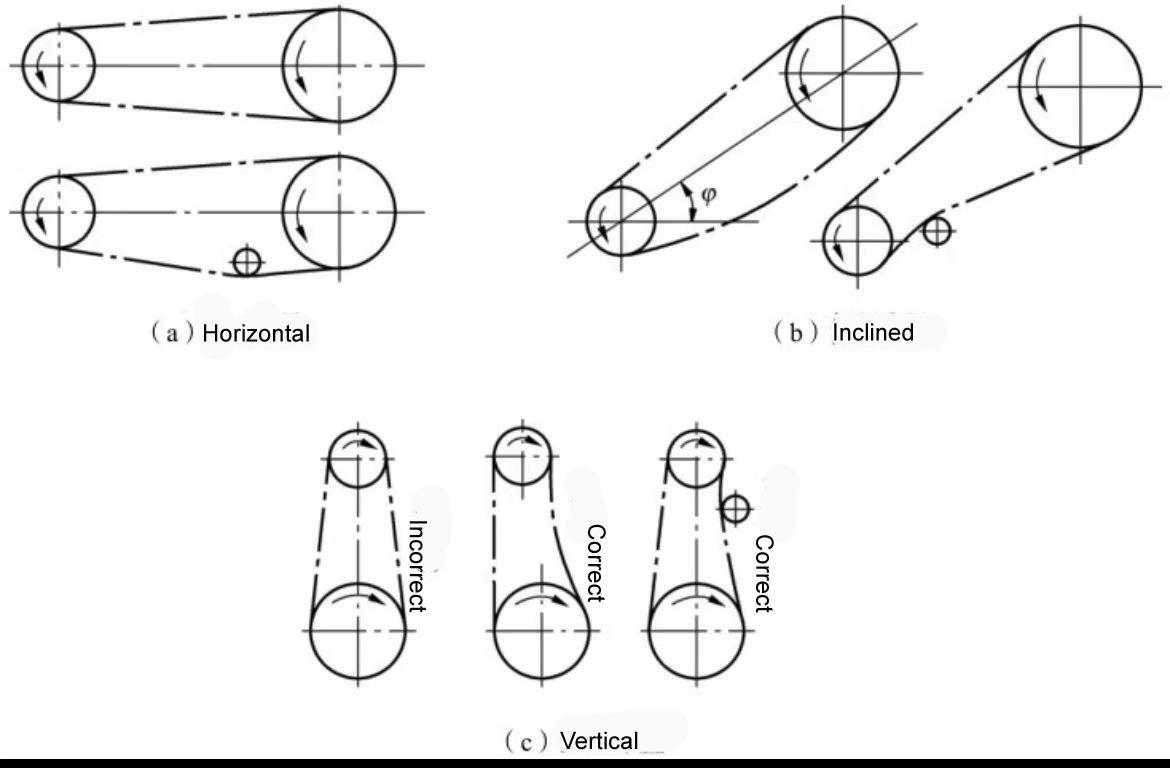

Ukuhlelwa kwedrayivu yakho yeketanga kubaluleke kakhulu njengezingxenye ngokwazo. Ukuhlelwa okuvamile kwedrayivu yeketanga kuboniswe ngezansi.

Ukuhlelwa Okuvundlile: Qinisekisa ukuthi izindiza ezijikelezayo zazo zombili izinhlayiya ziqondile ngaphakathi kwendiza efanayo eqondile nokuthi ama-axes azo ahambisana ukuvimbela ukuhlukana kweketanga nokuguguleka okungavamile.

Ukuhlelwa Okuthambekele: Gcina i-engeli phakathi kwemigqa ephakathi yama-sprocket amabili kanye nomugqa ovundlile incane ngangokunokwenzeka, okungcono kube ngaphansi kuka-45°, ukuze ugweme ukuhlangana kabi kwe-sprocket engezansi.

Ukuhlelwa Okuqondile: Gwema ukuba nemigqa ephakathi yama-sprocket amabili ekhoneni elingu-90°; esikhundleni salokho, susa ama-sprocket aphezulu naphansi kancane ohlangothini olulodwa.

Ukubekwa Kweketanga: Beka uhlangothi oluqinile lweketanga phezulu kanye nohlangothi olugobile ngezansi ukuze uvimbele ukugoba ngokweqile, okungaholela ekuphazamisekeni kwamazinyo e-sprocket.

Ukucindezeleka Kokusebenza Okuhle Kakhulu

Ukucindezela okufanele kwe-chain drive kubalulekile ukuvimbela ukuwohloka okukhulu, okungaholela ekungahlangani kahle nasekudlidlizeni. Uma i-engeli phakathi kwama-axis ama-sprocket amabili idlula ama-60°, ngokuvamile kusetshenziswa idivayisi yokucindezela.

Kunezindlela ezahlukahlukene zokuqinisa umfutho, okuvame kakhulu ukulungisa ibanga eliphakathi nokusebenzisa amadivayisi okuqinisa umfutho. Uma ibanga eliphakathi lilungiseka, ungalishintsha ukuze ufinyelele ukuqina okufiselekayo. Uma kungenjalo, isondo lokuqinisa lingangezwa ukuze kulungiswe ukuqina. Leli sondo kufanele libekwe eduze kohlangothi oluxegayo lwe-sprocket encane, futhi ububanzi balo kufanele bufane nobe-sprocket encane.

Ukubaluleka Kokugcoba

Ukugcoba kubalulekile ekusebenzeni kahle kwama-chain drive, ikakhulukazi ekusetshenzisweni kwesivinini esikhulu kanye nemithwalo esindayo. Ukugcoba okufanele kunciphisa kakhulu ukuguguleka, kunciphisa imiphumela, kuthuthukisa umthamo womthwalo, futhi kwandise isikhathi sokuphila kwe-chain. Ngakho-ke, kubalulekile ukukhetha indlela efanele yokugcoba kanye nohlobo lokugcoba ukuqinisekisa ukusebenza kahle.

Izindlela Zokugcoba:

Ukugcoba Okuvamile Ngesandla: Le ndlela ihilela ukusebenzisa ithini likawoyela noma ibhulashi ukufaka uwoyela ezikhaleni eziphakathi kwamapuleti okuxhumanisa angaphakathi nangaphandle ohlangothini olugoqekile lweketanga. Kunconywa ukwenza lo msebenzi kanye ngeshifti ngayinye. Le ndlela ifanelekela amadrayivu angewona abalulekile anejubane leketanga elingu-v ≤ 4 m/s.

Ukugcotshwa Kwamafutha Okuconsisa: Lolu hlelo lunebhokisi langaphandle elilula, lapho uwoyela uconselwa khona ezikhaleni eziphakathi kwamapuleti okuxhumanisa angaphakathi nangaphandle ohlangothini olugoqekayo ngendebe kawoyela nepayipi. Kumaketanga anomugqa owodwa, izinga lokuhlinzekwa kukawoyela livame ukuba ngamaconsi angu-5-20 ngomzuzu, kanti inani eliphezulu lisetshenziswa ngesivinini esiphezulu. Le ndlela ifanele amadrayivu anejubane leketanga elingu-v ≤ 10 m/s.

Ukugcoba Ngebhavu Lamafutha: Kule ndlela, ikesi langaphandle elingavuzi livumela uchungechunge ukuthi ludlule endaweni yokugcina uwoyela evaliwe. Kumelwe kuqashelwe ukugwema ukucwilisa uchungechunge ngokujulile kakhulu, njengoba ukucwilisa ngokweqile kungaholela ekulahlekelweni okukhulu kwamafutha ngenxa yokushukuma futhi kungabangela ukuba uwoyela ushise kakhulu futhi wonakale. Ukujula kokucwilisa okungu-6-12 mm ngokuvamile kuyanconywa, okwenza le ndlela ifaneleke kuma-drive anejubane leketanga elingu-v = 6-12 m/s.

Ukugcotshwa Kokuphakelwa Kwamafutha Okusanhlamvu: Le ndlela isebenzisa isitsha esivaliwe lapho uwoyela ugcotshwa khona yipuleti lokusanhlamvu. Uwoyela ube usuqondiswa eketangeni ngedivayisi yokuqoqa uwoyela esikhaleni. Ukujula kokucwiliswa kwepuleti lokusanhlamvu kufanele kugcinwe ku-12-15 mm, futhi isivinini sepuleti lokusanhlamvu kufanele sidlule ku-3 m/s ukuqinisekisa ukugcotshwa okusebenzayo.

Ukugcoba Ngengcindezi: Kule ndlela ethuthukisiwe, uwoyela ufafazwa eketangeni kusetshenziswa ipompo kawoyela, kanti i-nozzle ibekwe kahle endaweni lapho iketangeni lihlangana khona. Uwoyela ojikelezayo awugcini nje ngokuthambisa kodwa futhi unikeza umphumela wokupholisa. Ukutholakala kukawoyela kwe-nozzle ngayinye kunganqunywa ngokusekelwe ekuphakameni kweketangeni kanye nesivinini ngokubheka izincwadi ezifanele, okwenza le ndlela ifaneleke kuma-drive anamandla aphezulu anejubane leketangeni elingu-v ≥ 8 m/s.

Ukuze ufeze ukusebenza kahle kanye nokusebenza kahle ezinhlelweni zakho zemishini, kubalulekile ukuqonda izici ezibalulekile zokukhetha nokunakekela ama-sprocket eketanga. Ungashiyi impumelelo yemishini yakho ngengozi—yenza izinqumo ezinolwazi eziletha imiphumela ehlala njalo!

Ukukhetha izinto zokwakha ezifanele, ubukhulu, kanye namasu okulungisa kubalulekile ukuqinisekisa ukuthi imisebenzi yakho isebenza kahle futhi ngempumelelo. Ngokubeka lezi zici phambili, ungathuthukisa isikhathi eside kanye nokuthembeka kwemishini yakho.

Uma unemibuzo mayelana nama-sprocket noma udinga isiqondiso sochwepheshe, sicela ungangabazi ukuxhumana nathi ku-export@cd-goodwill.comIthimba lethu elizinikele lilapha ukuzokusiza ngazo zonke izidingo zakho ze-sprocket!

Isikhathi sokuthunyelwe: Novemba-21-2024